The motor control centre (MCC) is a critical point of communication between the mechanical and electrical designs. The Flow electrical team thoroughly coordinated the electrical requirements with the mechanical system to ensure the appropriate equipment requirements, including potential for future growth.

Projects

West Village Energy Centre

West Village Energy Centre

The West Village Energy Centre is the first facility of its type for the City of Surrey. The facility acts as the backbone of Surrey City Energy by generating heating water that is then distributed through an underground pipe network to dozens of connected buildings. The energy centre plays a pivotal role in helping the municipality reach its greenhouse gas emission targets. Indeed, the majority of the natural gas used at the West Village Energy Centre is in the form of Renewable Natural Gas (RNG) produced at the Surrey Biofuel Facility. The Flow electrical team provided a complete electrical, fire alarm and communication system design for this transformative facility.

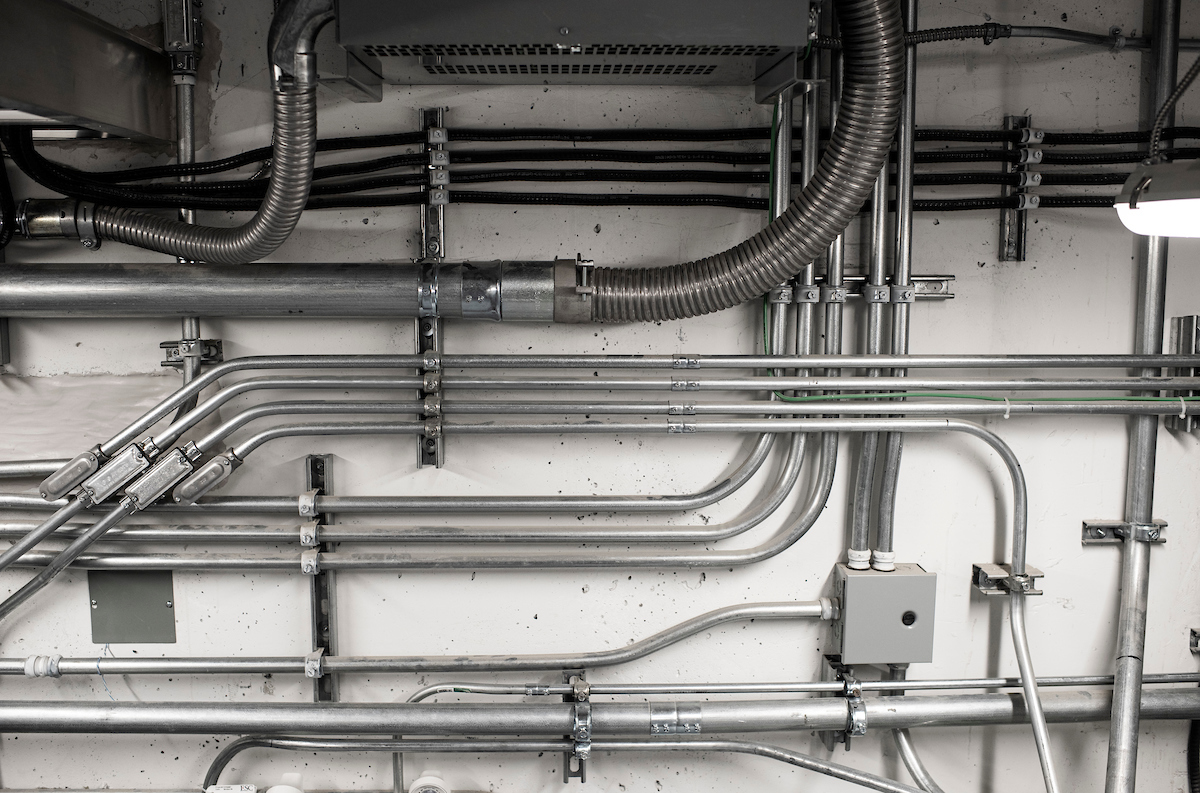

Tucked away at high elevation inside the electrical room, this section of wall would likely go unnoticed by most. However, to our electrical engineers it immediately stands as a statement of the complexity of electrical design, and the importance of maintaining a thoughtful, organized and smart approach. The superb workmanship in this photo of the electrical contractor echoes the standard of quality we provide in our designs.

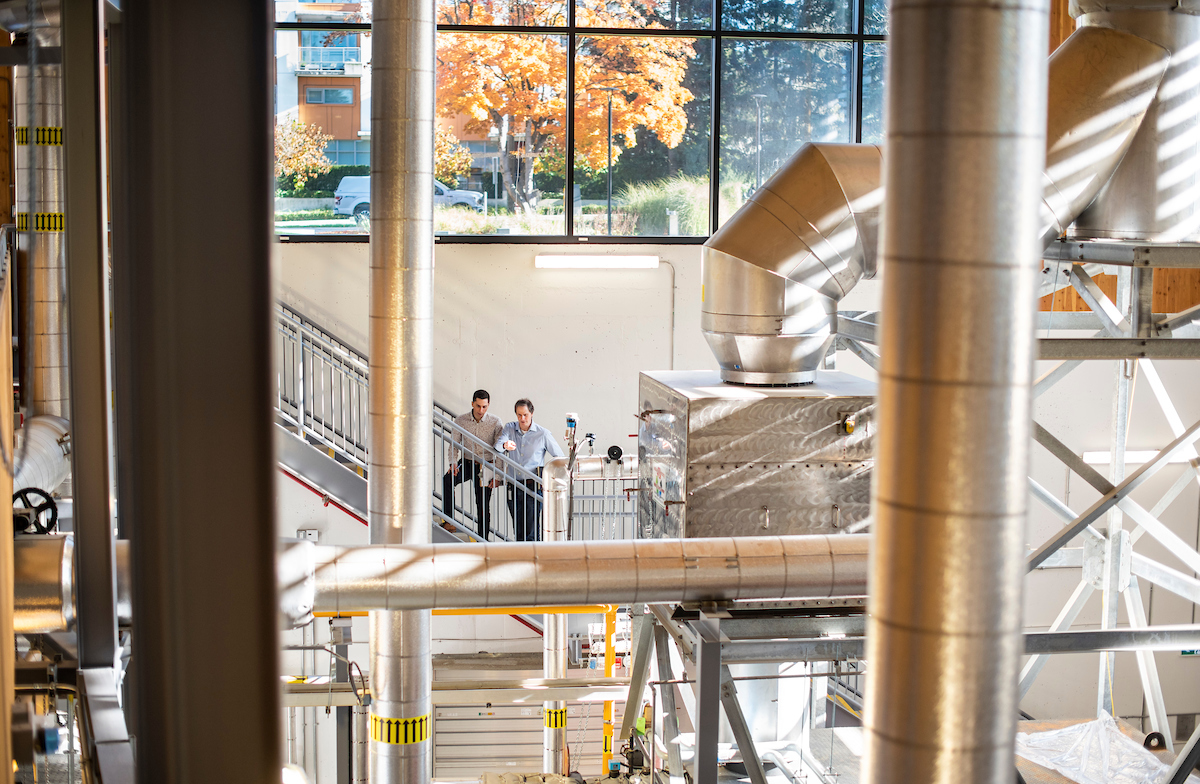

The facility includes two large, natural-gas fired boilers located in the centre of the space. The electrical scope included design and specification of pull boxes, breakers, wire sizing and all required components to complete the power connections. The facility has set of stairs along the back that offer a great overview of the entire area!

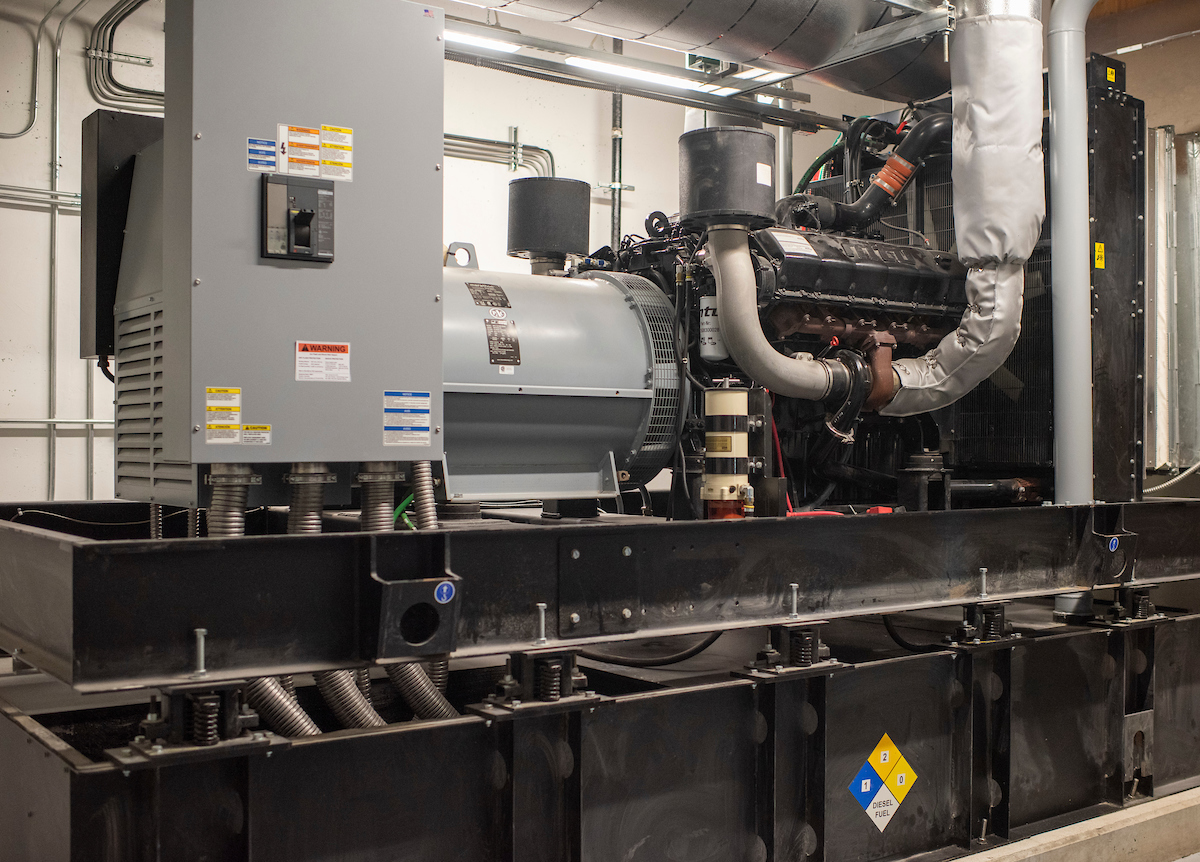

What happens when the power goes out? A critical facility such as this needs to have backup power in the event the general power grid is offline. In this case, the backup source is a 600kW electrical generator connected to select portions of the electrical distribution through automatic transfer switches. The Flow team worked closely with the municipality and facility operators to determine the required size of the electrical generator, balancing sufficient capacity for the connected loads without over-designing.

The building is home to a high-voltage (25kVA) electrical service from BC Hydro that is then stepped down at an exterior unit sub-station with a 2000kVA transformer and Vacuum Fault Interruption (VFI) switchgear. Unit sub-stations can be located on the interior or exterior of the building and have strict and differing requirements depending on the installation location. In collaboration with the architect and municipality, the Flow team led an analysis to determine the optimal installation location.