The challenge of this project was aligning the mechanical and electrical services with the building structure. The building’s massing, made up of steel columns and beams that sit below each floor slab and span the entire width of the building, splits the ceiling into a series of bays. Crossing services from one bay to another would have required a number of offsets in the services and impacted the building aesthetics. To avoid this, Flow designed an equipment layout to maintain the cleanest lines, with major services running north-south along the building to mirror the footprint of the space. We tucked the main ductwork branch into the left corner, with take-offs coming off the top of the main, running tight to the slab’s underside and into the ceiling cassette units.

Projects

169 W 7th Ave

169 W 7th Ave

Located in Vancouver’s Mount Pleasant neighbourhood, 169 W 7th Ave raises the bar for both aesthetic and systems design. The Flow team leveraged unique technologies for the mechanical and electrical systems to elevate the sustainability of the building and improve the experience of its users. Notably, the building uses an air-cooled heat recovery variable refrigerant flow (VRF) system, which can significantly reduce the amount of external energy required for heating, cooling and ventilating by transferring surplus heat in one area to another space that needs it. All the mechanical operates solely on renewable hydro-electricity, notably contributing to our goal of reducing greenhouse gas emissions in commercial applications.

The VRF system inside this building has three main components: an outdoor, air-cooled heat pump; fan coil unit; and branch control (BC) boxes that direct refrigerant between fan coil units to the outdoor unit in an optimized manner to maximize energy recovery. Within the open areas, four-way ceiling cassettes were specified with careful consideration of their abilities to circulate air throughout the entire occupied area to minimize stratification. Their location was coordinated with that of the lighting fixtures to ensure there were no conflicts and that air movement did not cause swaying of lights.

Fire alarm systems play a critical role in life safety within buildings. The Flow team designed a new and complete fire alarm system for the building that included a number of unique requirements emerging from the building’s Alternative Solutions. This photo shows various fire alarm input and output modules for the building’s smoke detectors.

The outdoor components of the VRF system include three 10TR air-cooled heat pump units. These units run refrigerant through a series of coils and valves while a fan circulates air across the coils, extracting or rejecting heat from the atmosphere depending on the mode they’re operating in. While the heat pumps are capable of operating at a range of outdoor air temperatures, their capacity becomes derated when operating at extreme highs and lows. During the mechanical design phase, it was crucial for the Flow team to consider the capacity of the units to ensure they would work appropriately at all times of the year.

To provide flexibility for potential tenants, the Flow team designed a new 600V, 400A electrical service for the building. This optimized design permitted all of the electrical equipment to be located inside of a closet, including a 225KVA transformer, splitters and distribution panels. The closet is cooled by a dedicated refrigerant fan coil unit tied into the basement level’s VRF piping network. To follow best practices, the fan coil unit was located outside of the electrical room to minimize potential damage from condensation.

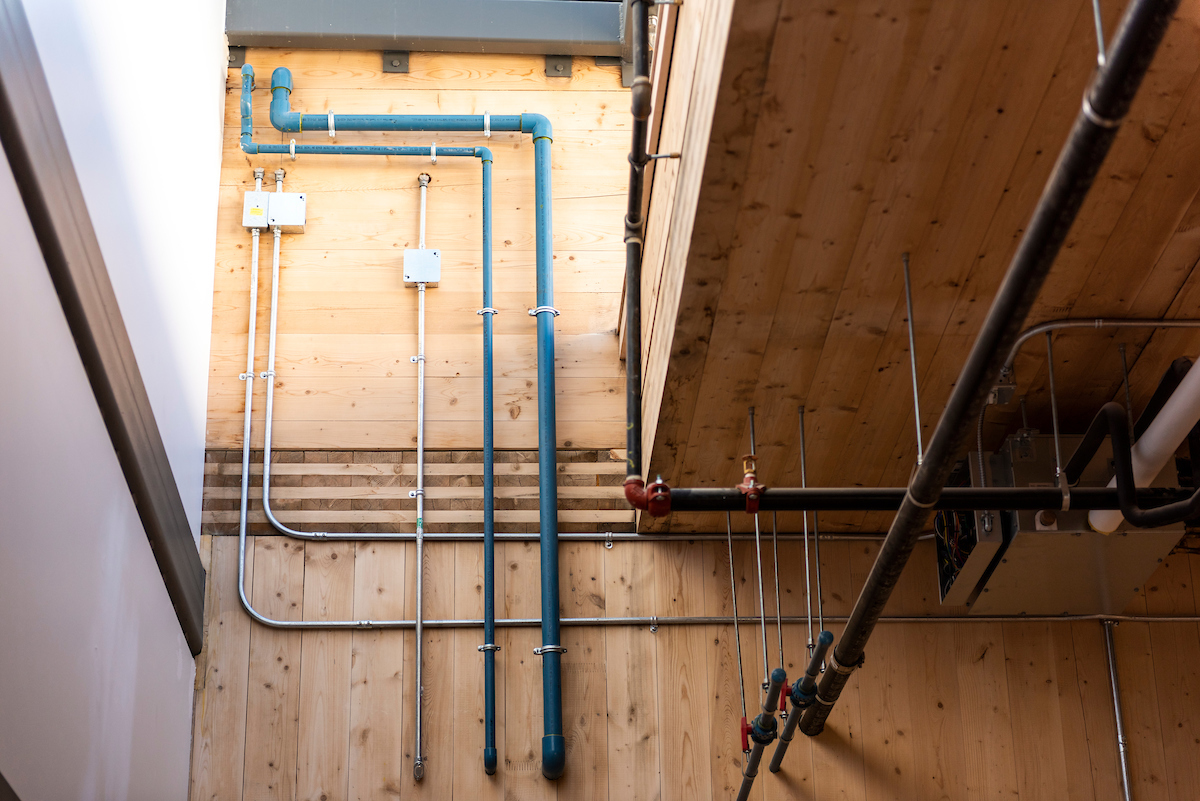

You can see a BC box in this image. These boxes are connected to each fan coil unit with two refrigerant pipes, each with its own solenoid valve. As the opening and closing of these valves is audible, it’s crucial to carefully consider their location – you don’t want it above someone’s workstation! For this project, Flow located all BC boxes near the washrooms, where sound level requirements are less stringent. This image is also a shout-out to the trades who worked on this project, as it is a clear indication of their efforts to run services cleanly, neatly and in an organized manner.