BC continues to bring the heat when it comes to innovation in HVAC and building systems! This year’s ASHRAE Chapter and Region XI Technology Awards highlight just how strong our local talent is. Flow Engineering is proud to have won an award in the Existing Buildings category.

News

ASHRAE BC Chapter Award Winner: Bentall 4 Pressurization

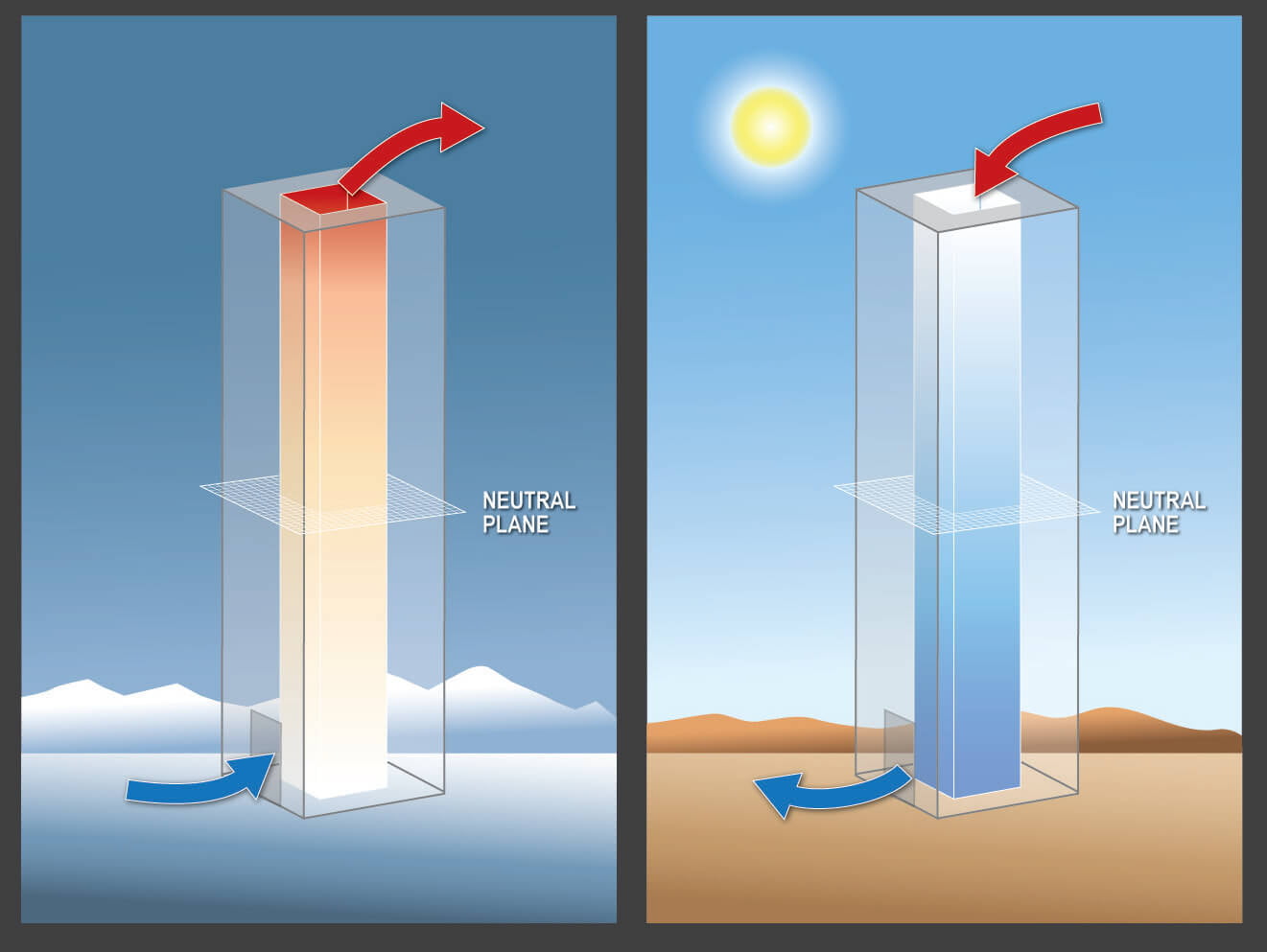

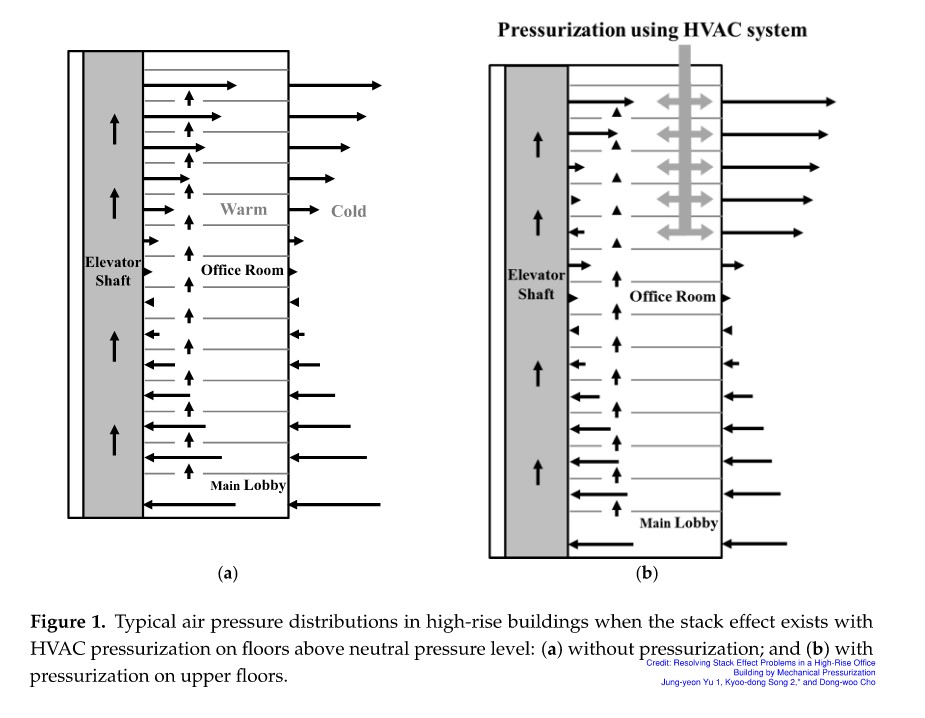

Bentall Tower 4 is a commercial high-rise tower located in downtown Vancouver, BC. During winter months, the building experienced elevated stack effect conditions, which presented challenges with maintaining consistent building pressurization. These imbalances contributed to reduced energy efficiency and influenced elevator performance, especially near the lobby.

The air pressure differentials caused by stack effect made it more difficult for elevator doors to open and close properly. In some cases, this momentarily prevented elevator cab movement. While no failures occurred, these events created noticeable disruptions that impacted building

operation.

To improve comfort, performance, and overall system balance, the project team implemented a pressurization optimization strategy focused on mitigating stack effect while enhancing energy performance and maintaining elevator reliability.

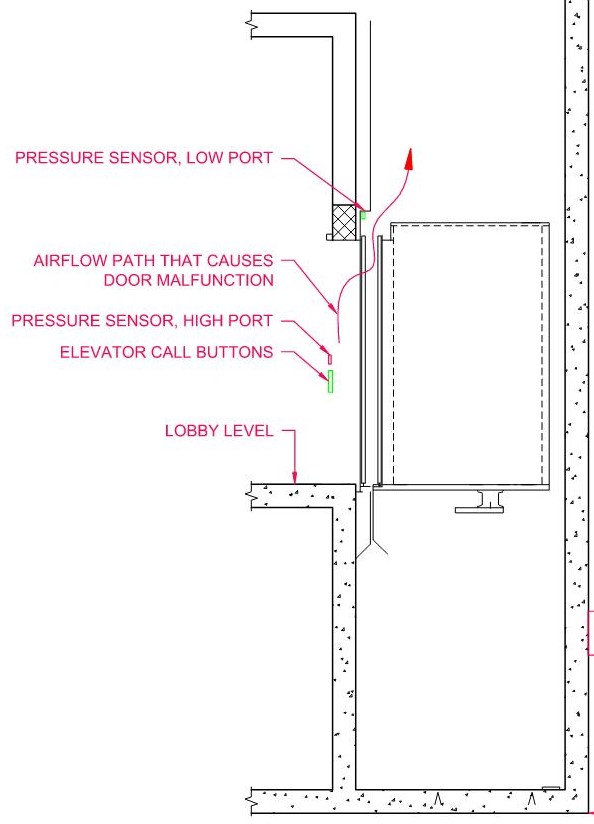

To better understand and manage vertical air pressure within the building, differential pressure (DP) sensors were installed at the lobby, 4th, 15th, and 35th floors, as well as across the elevator shaft and adjacent

lobbies.

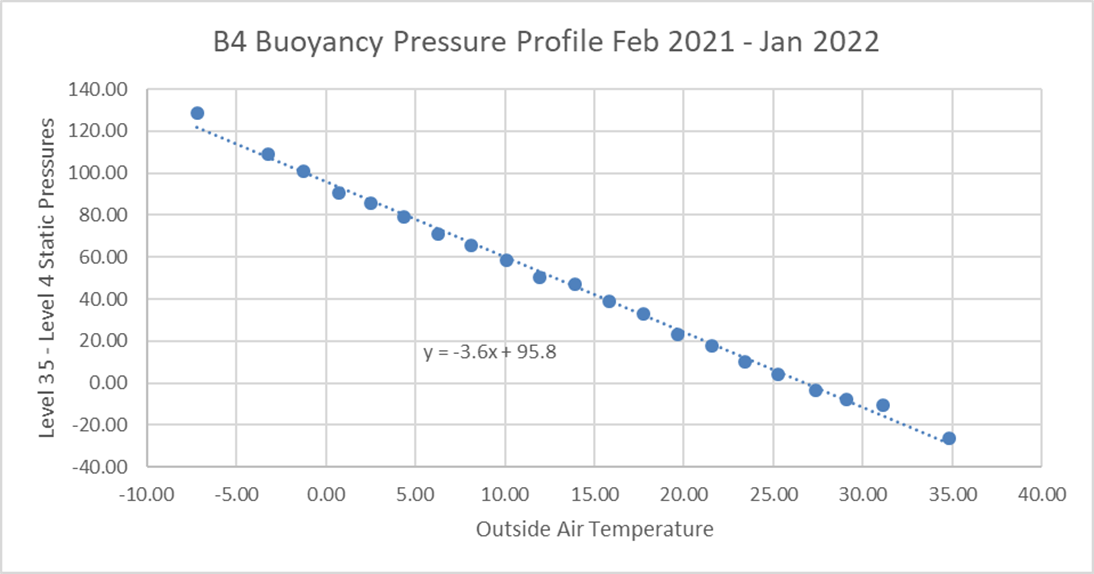

Using this network, the team assessed the natural buoyancy profile of the building — measuring how stack-driven pressure differentials developed at different outdoor air temperatures when HVAC systems were off. This data was used to define a dynamic reset strategy, establishing maximum and minimum setpoints for differential pressure at the 35th floor, optimized for seasonal conditions.

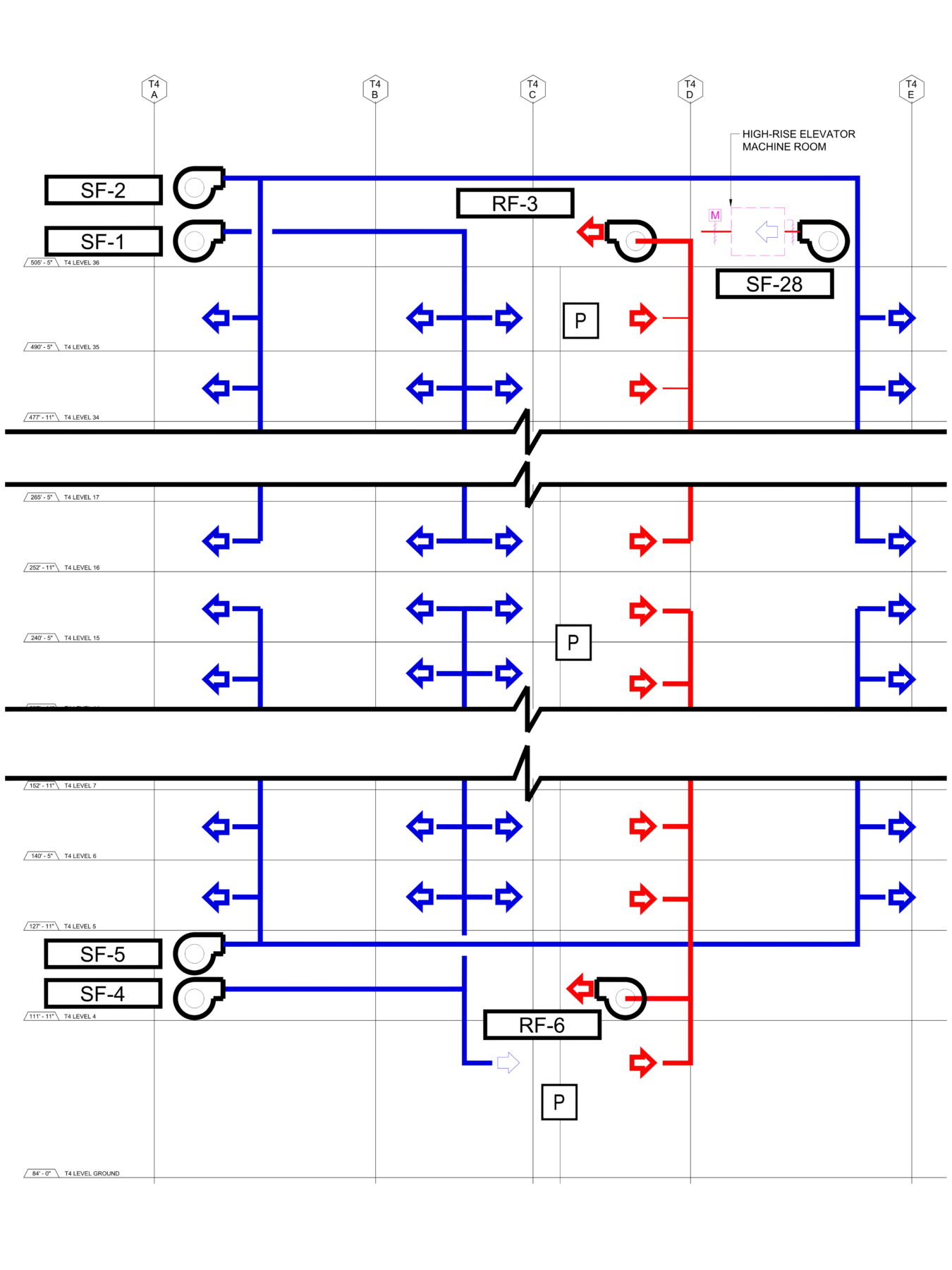

The tower is served by two main HVAC systems:

• A low-rise system from the lobby to the 15th floor.

• A high-rise system from the 16th to the 35th floor.

The optimization centered around modulating the high-rise return fan in response to live DP readings.

This allowed the system to counteract stack effect by adjusting airflow and creating a form of “air plug” near the top of the building. This dynamic response helped stabilize pressure throughout the vertical shaft.

Elevator door performance was observed to correlate with certain shaft-to-lobby pressure differentials. A threshold was established just below the level where door operation began to be affected. If this critical pressure limit is reached, the system takes two automated actions:

• Basement-level relief dampers open, allowing air to enter the elevator shaft from a less disruptive location, rather than the main lobby.

• All HVAC equipment and dampers are reset to automatic control, ensuring coordinated system behavior and avoiding unintended pressure imbalances due to manual overrides.

In addition, motorized dampers were added to the elevator machine room supply and relief air ducts. Previously, the relief path did not include a controllable damper, allowing excessive air to escape through the penthouse. With the addition of operable dampers, airflow can now be regulated more effectively, minimizing

pressure losses through the elevator machine room.

All modifications were developed in collaboration with Technical Safety BC, elevator maintenance provider, and controls contractor to ensure proper integration and safety compliance.

To refine the system:

• A rolling 5-minute average of the elevator shaft DP was used to filter out short-term swings caused by elevator motion (piston effect).

• Seasonal DP reset values were based on real-world data and validated against building behavior across a range of conditions.

• A structured testing and commissioning program was carried out over two years to fine-tune response parameters, confirm system stability, and support operations.

A special shout out to our client, Hudson Pacific Properties for trusting us with this project, and our trade partners Ainsworth Controls, and TKE.